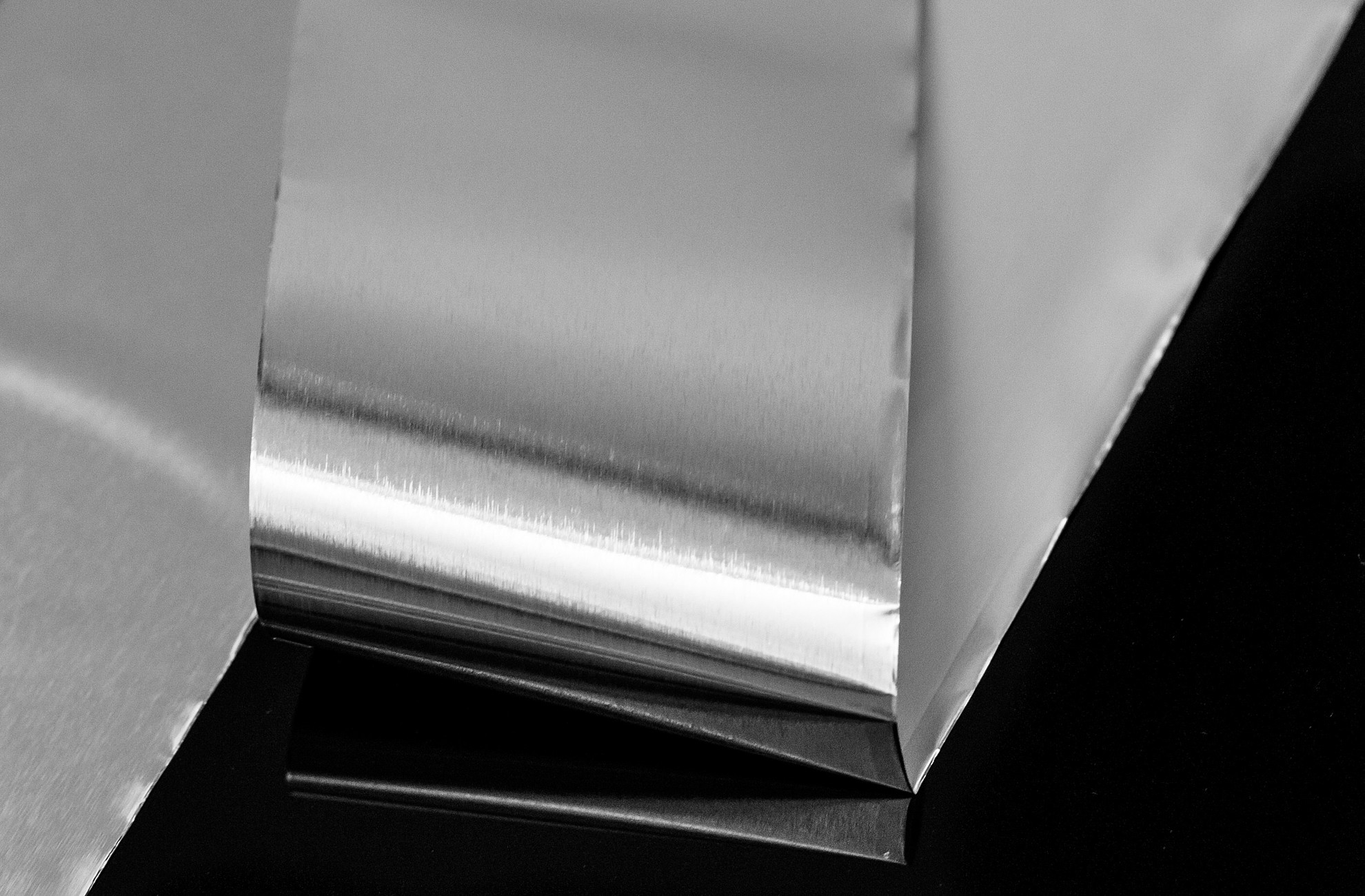

Pure aluminium foil or aluminium foil as needed

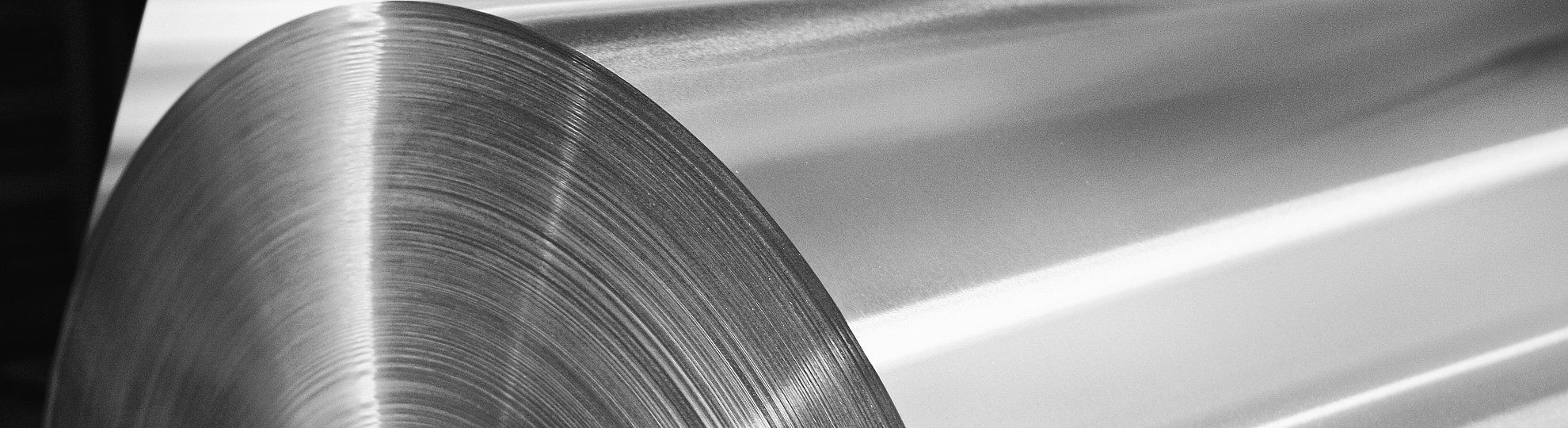

Thick and thin

We produce for you hard and soft, smooth and embossed pure aluminium foils as thin foils for example in 10, 15, 20 µm and as stronger foils 30 – 300 µm. Even oversize widths are possible.

Alloy

Aluminium with a purity of 99 % or higher is called pure aluminium. Primary aluminium, i.e. the metal produced in an electrolytic furnace, contains a series of "impurities". In general, however, only the elements iron and silicon are present in quantities exceeding 0.01 %.

With regards to aluminium foils > 0.030 mm (30 µm), the most common aluminium alloy is EN AW-1050: pure aluminium foil with an aluminium content of at least 99.5 %. (Aluminium > 0.300 mm is generally called aluminium strip or aluminium sheet.)

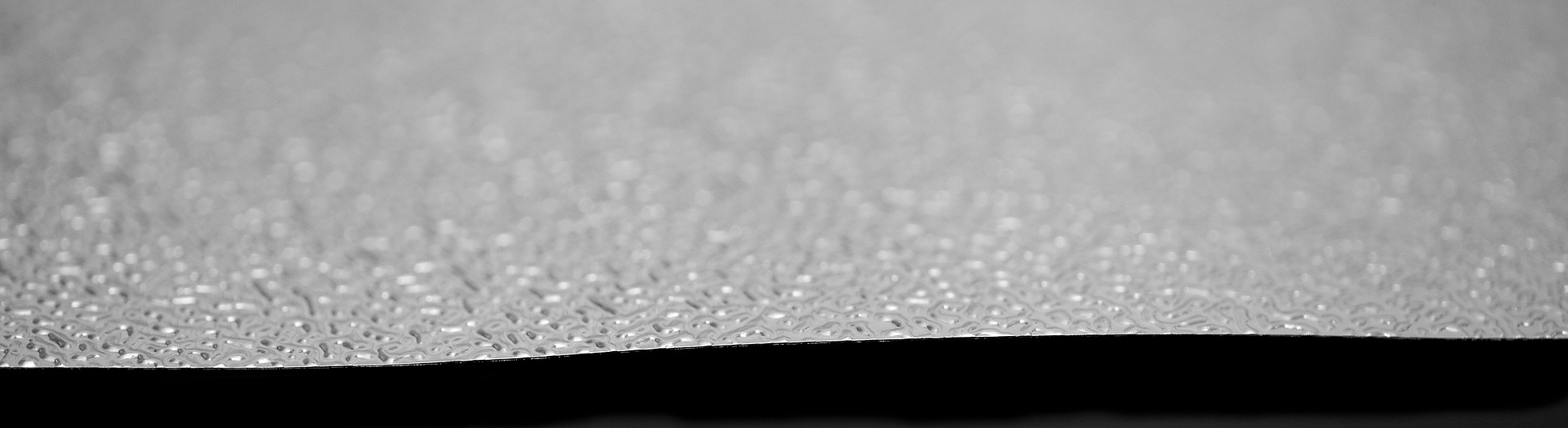

Shiny and matt

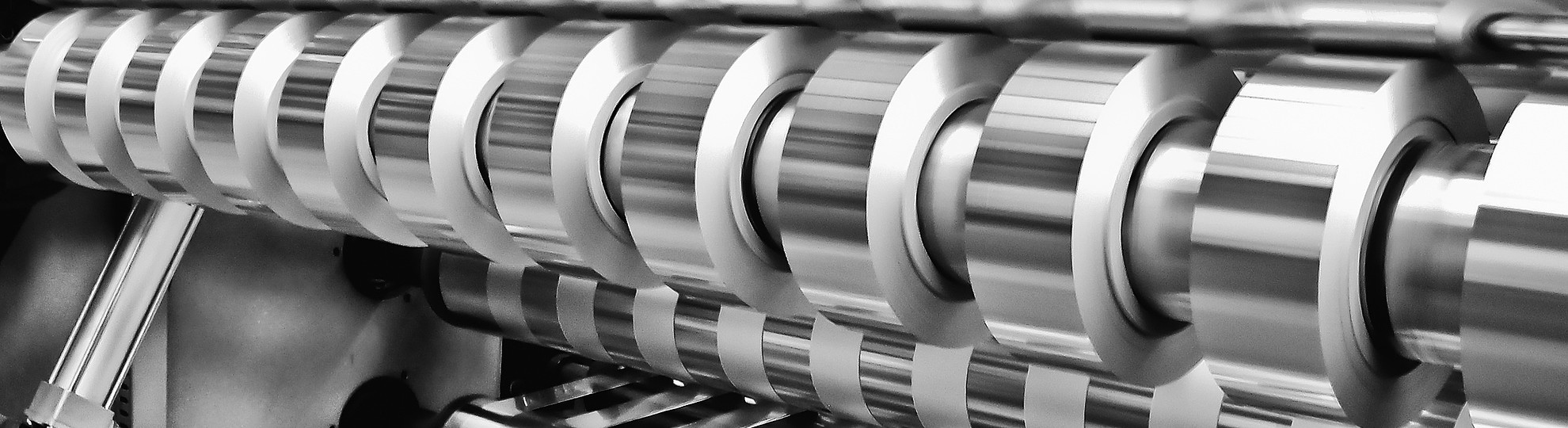

Aluminium foils are usually produced using pure aluminium (Al content 99 – 99.9 %). So-called pre-rolled strip with approx. 0.6 – 1.5 mm thickness is cold-rolled in several rolling steps (passes) to the required thickness.

In the production of very thin aluminium foil, two layers are rolled. This leads to two different surfaces (shiny and matt). The reason for this is that the outside surfaces come into contact with the polished rolling mill and therefore become relatively smooth (shiny), while the inside surfaces have a slightly more roughened surface due to free forming and thus appear matt.

The aluminium hardens during rolling due to the strong forming and this means that the aluminium becomes harder or stiffer. Subsequent soft annealing makes it soft and flexible again.

Frequently Asked Questions

What is pure aluminium foil?

Aluminium with a purity of 99 % or higher is referred to as pure aluminium. For aluminium foil > 30 µm, for example, the most common aluminium alloy is EN AW-1050, which stands for pure aluminium foil with an aluminium content of at least 99.5%.

What standard lengths do you have?

None, really. Dependent on the material thickness, we can produce rolls just 5 m in length or even roll lengths of up to 20.000 m, for example. Our standard product range provides a general overview.